Predictive Maintenance

Empower developers with end-to-end visibility from build to production.

ANTICIPATE FAILURES, NOT JUST RESPOND TO THEM

Before this solution, maintenance engineers relied on customer complaints and repeated site visits to diagnose issues with refrigeration units. This reactive approach led to costly equipment replacements and poor customer experience.I designed the initial experience to help maintenance engineers teach the AI what anomalies may look like. By enabling engineers to analyze equipment behavior and label anomalies, we accelerated the model’s learning while surfacing early warning signs of failure.

Complex Domain

Cross-functional Collaboration

MVP Design Under Ambiguity

MY ROLE

Principal UX Designer

COMPANY

Panasonic

IMPROVING ANOMALY DETECTION AND TEACHING AI

Initial predictive maintenance dashboard enabling engineers to label anomalies and train the model

BACKGROUND

Panasonic

Sells & Maintains Refrigerators

To

Large Scale

Grocery Stores

Nationwide UseAll Over Japan

PROJECT BACKGROUND

Top Frustrations Shared by VI Admins During Contexual Enquriry

The Data Science & Panasonic Cold Chain teams had spent 18 months building an AI model.

It was time to visualize this work. I had only 2 weeks of design time.

The biggest challenge? I didn’t know anything about the users and how do they mitigate issues.

I influenced the team to consider the MVP as an hypothesis to be validated post implementation

DESIGN WORKSHOP SESSIONS

Pre-Design Workshop for MVP Direction

Why it mattered:

Before designing the MVP, we needed clarity on:

- Project goals

- Target users

- The meaning of product scalability

Without this, the MVP risked misalignment with long-term vision.

What I did:

- Facilitated a pre-design workshop to gather diverse inputs

- Defined the agenda and prepared materials in advance

- Ensured participation from product, engineering, and business stakeholders

- Ran warm-up exercises to encourage open discussion

- Captured insights on user needs and scalability definitions

The result:

The session helped frame the MVP with shared understanding. It reinforced that design isn’t done in a silo and ideas emerged from across teams.

DESIGN WORKSHOP OUTPUT

Collaboration With Product Management, Engineering & Data Scientists

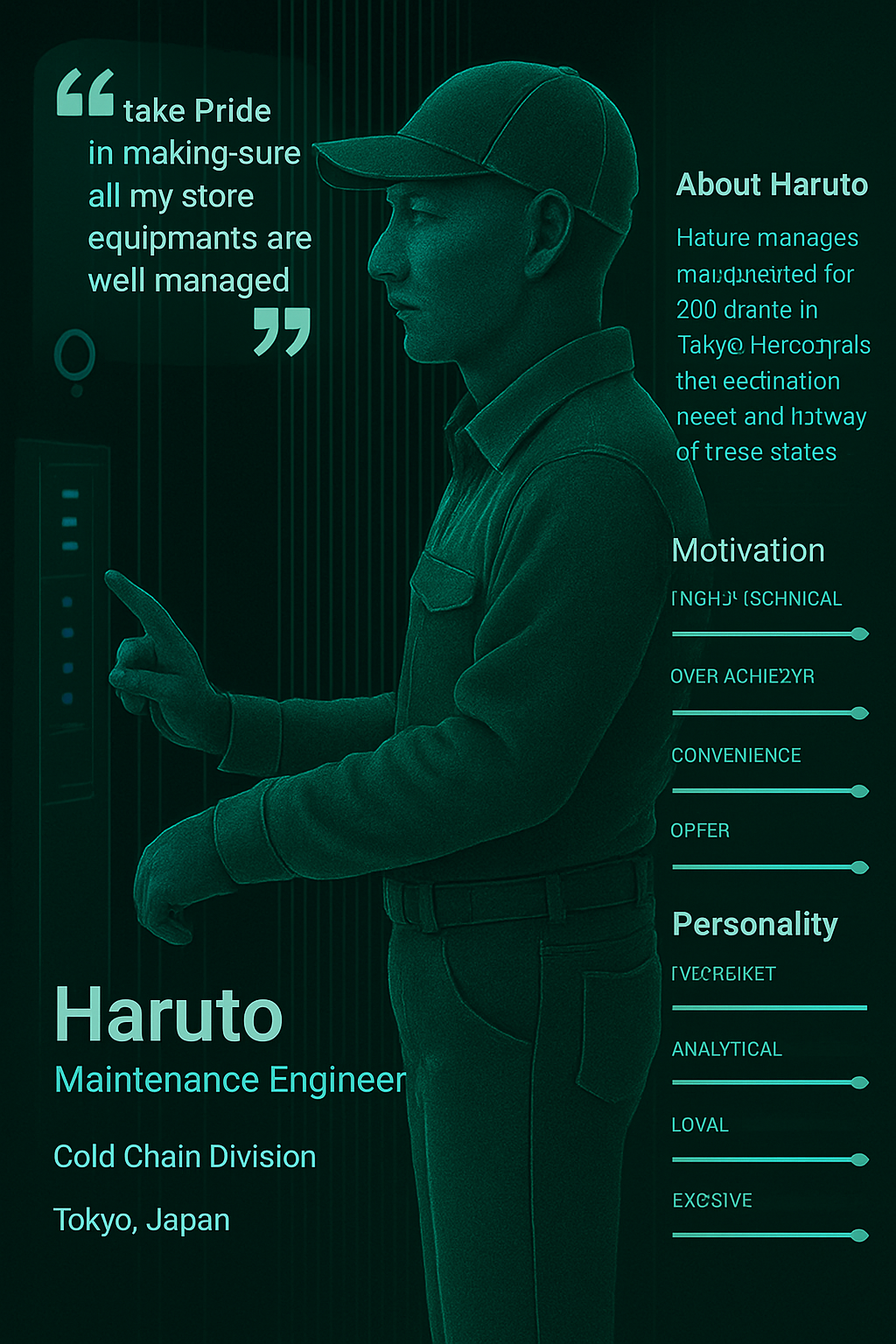

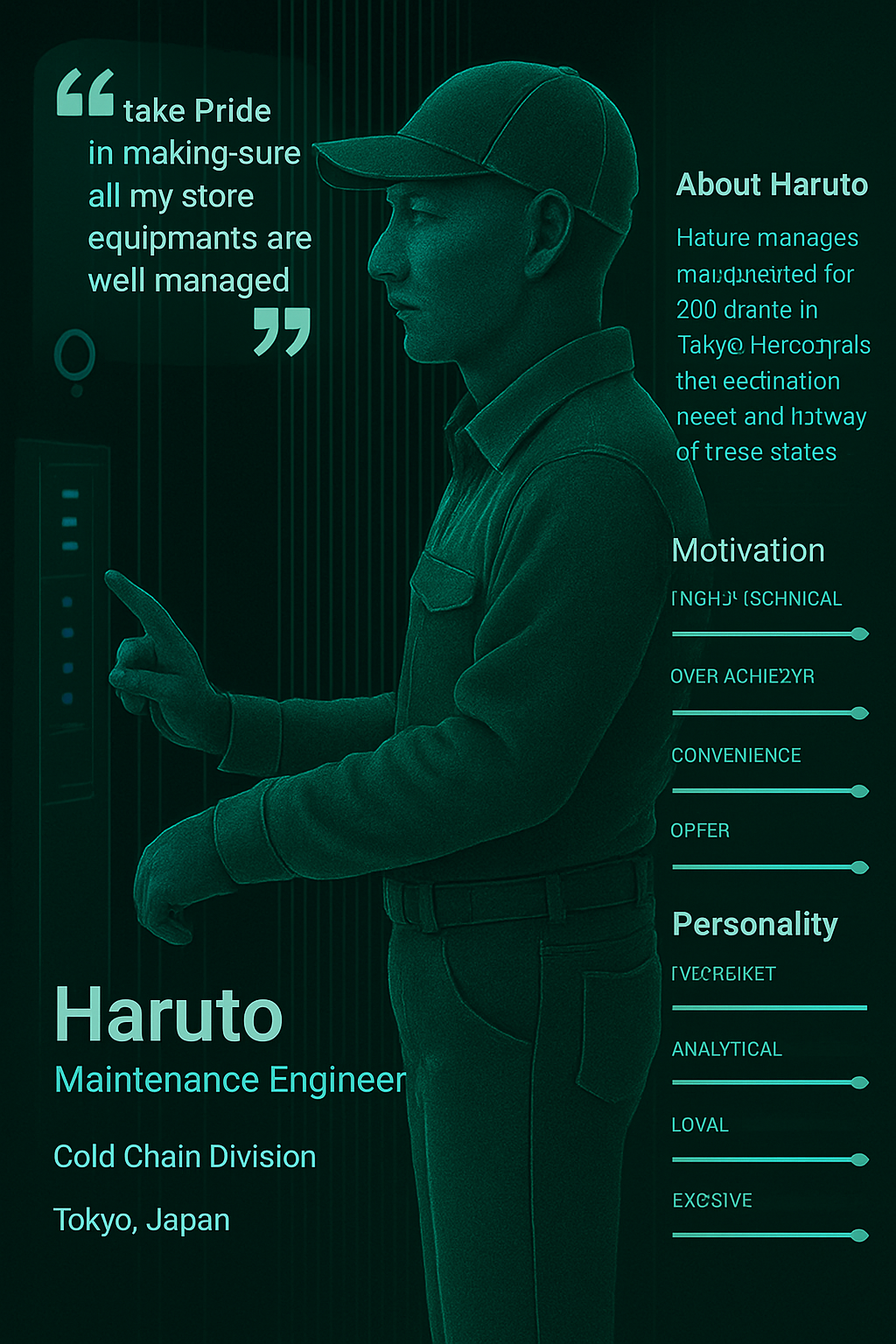

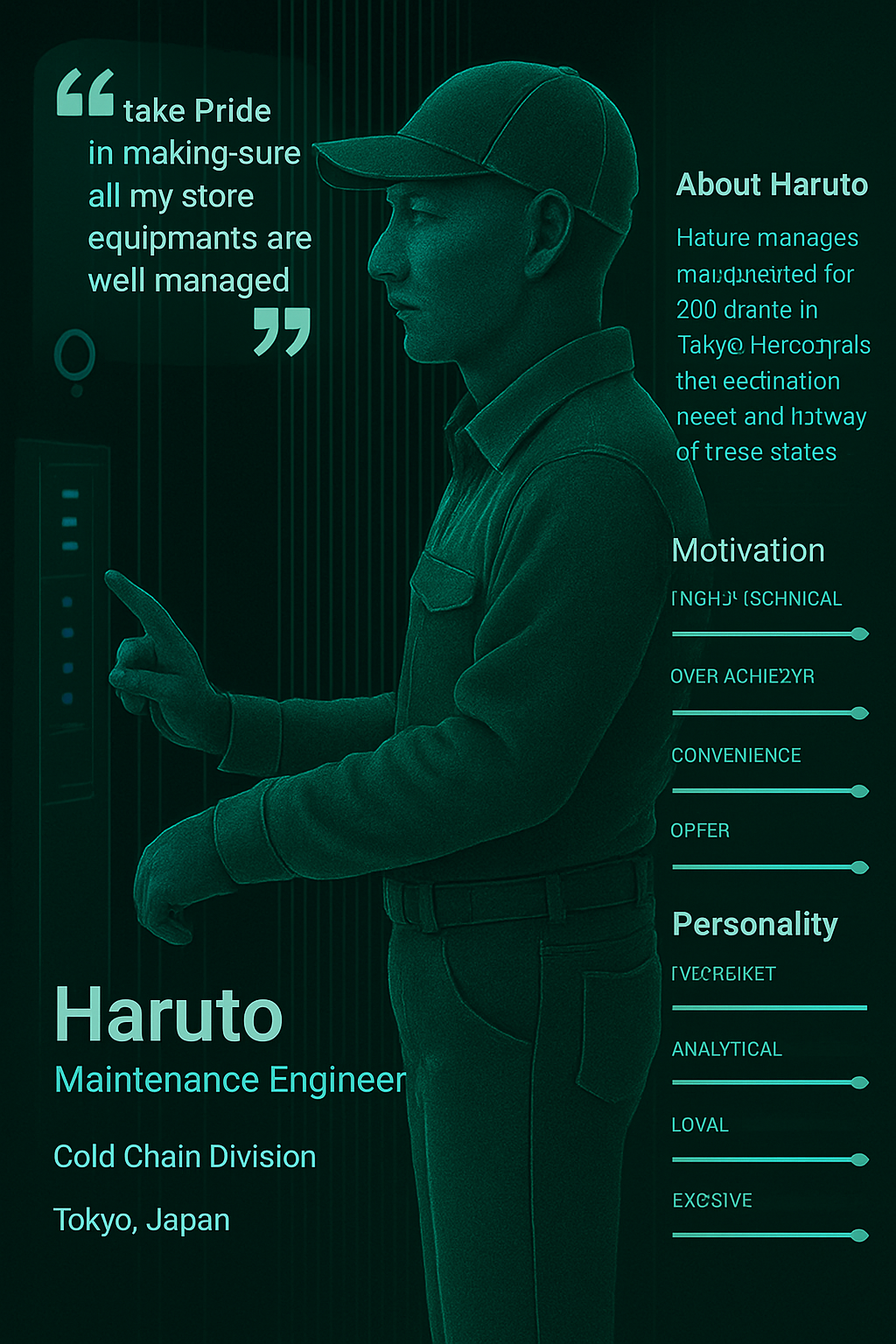

Persona

Created a fictional persona to help the team empathize with end users during early design conversations

Clearly communicated that the persona was a placeholder, and would be refined after conducting user research

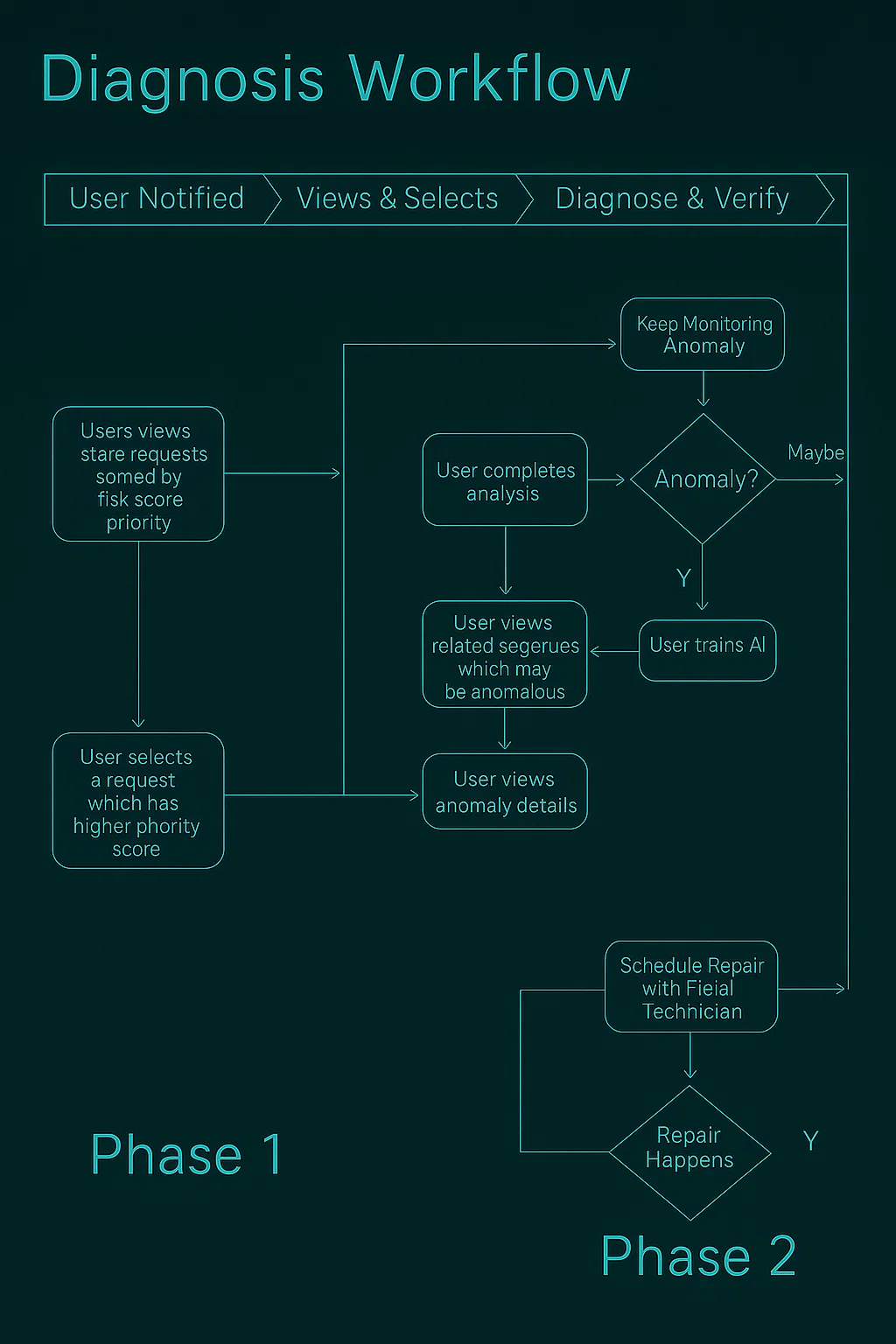

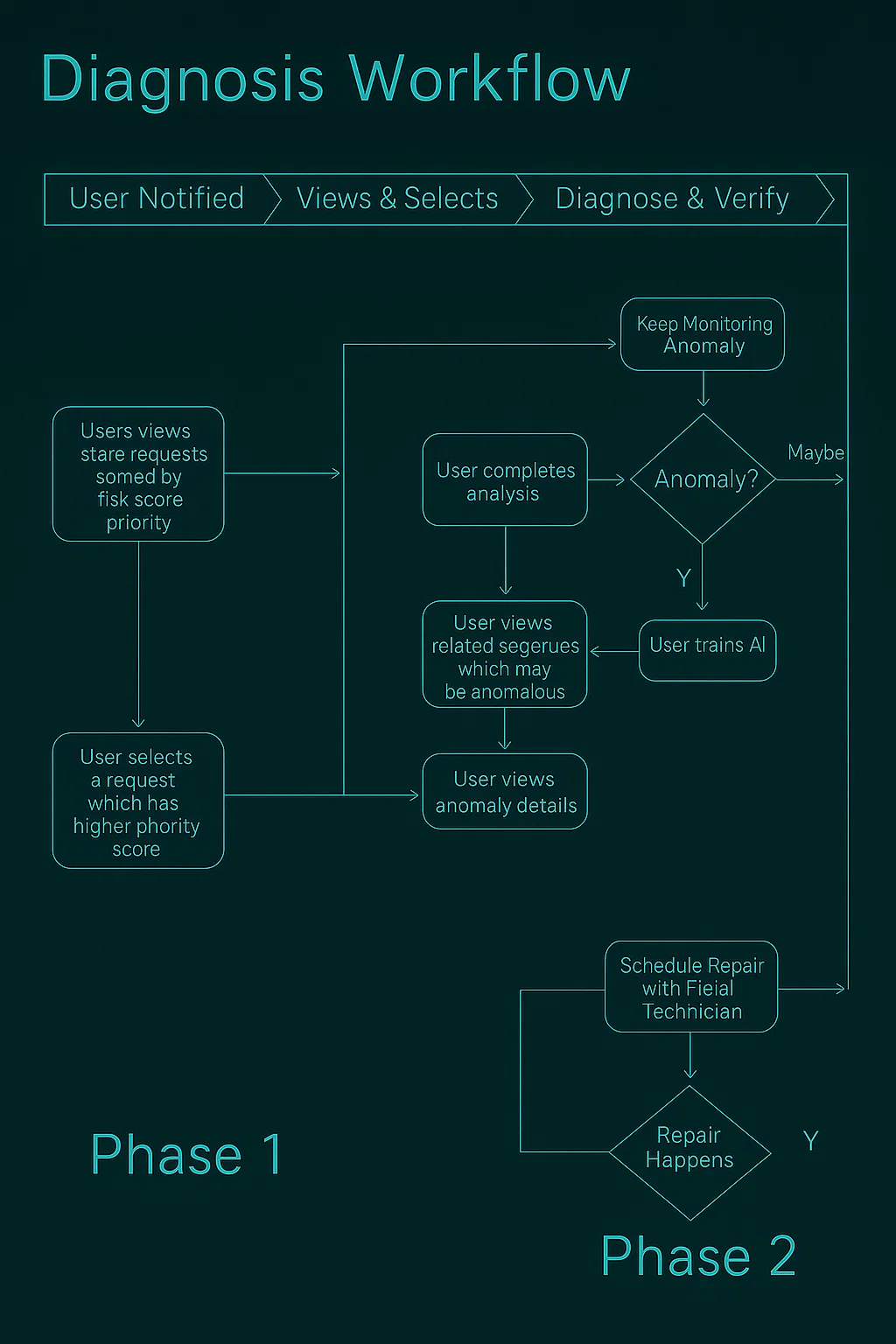

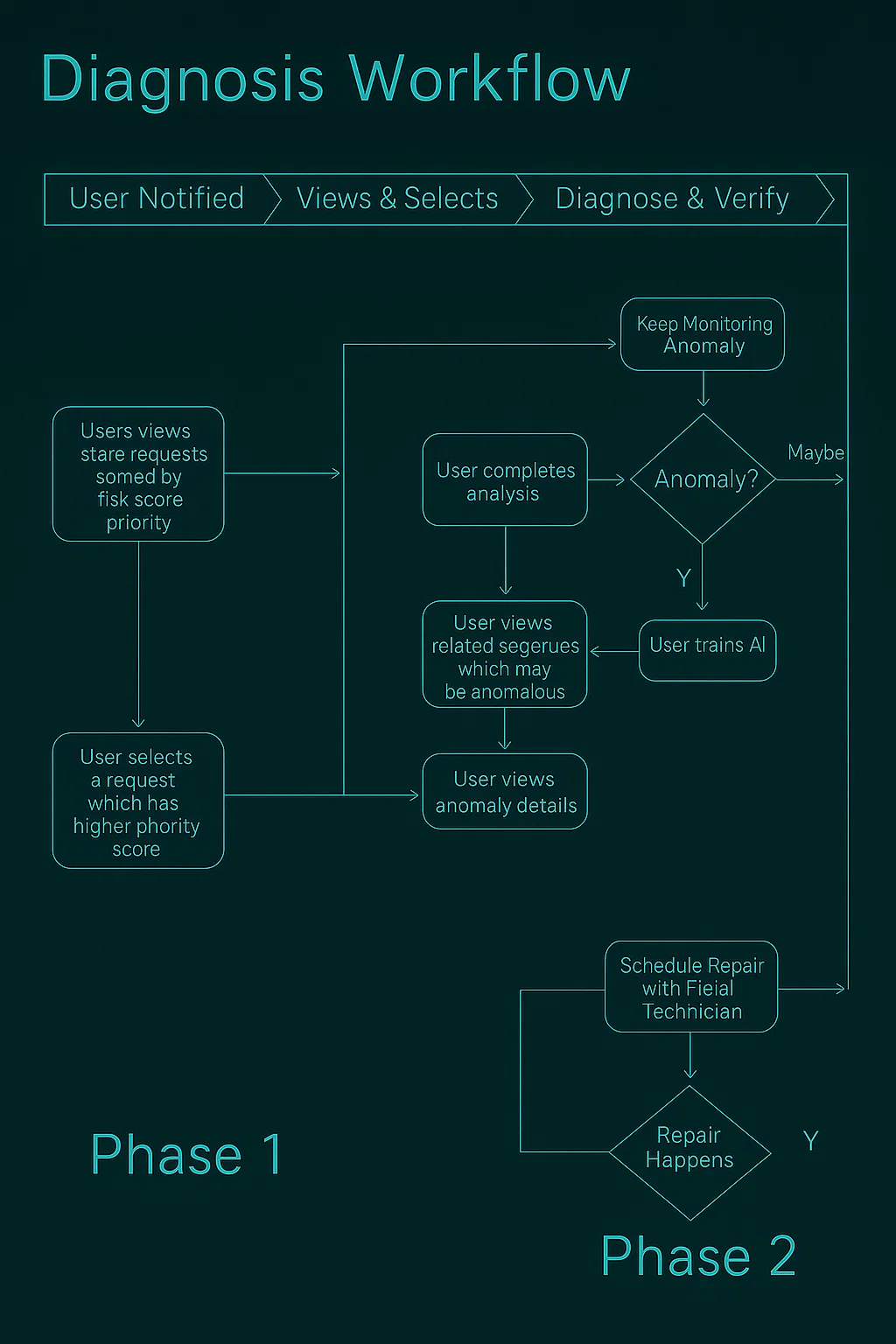

Task Flow

Created a draft task flow to help the team visualize the user journey for anomaly detection

Aligned on early user steps and system touchpoints to inform MVP direction

SETTING THE CONTEXT

Brought Clarity To An Ambiguous Problem Space

Brought clarity to troubleshooting by untangling alert noise and highlighting the true source of failure.

User Goal

Help Maintenance Engineers Diagnose Anomalous Equipment Cases Successfully

Success Criteria

Maintenance Engineers should be able to solve 10 Anomaly cases per day

DESIGN EXPLORATIONS

Exploration 1

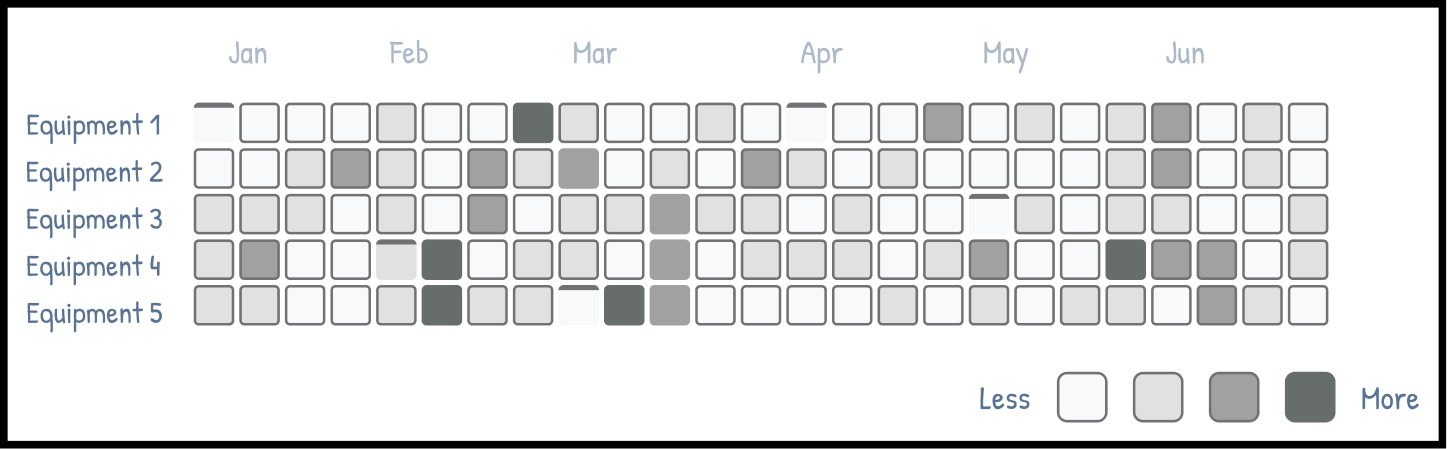

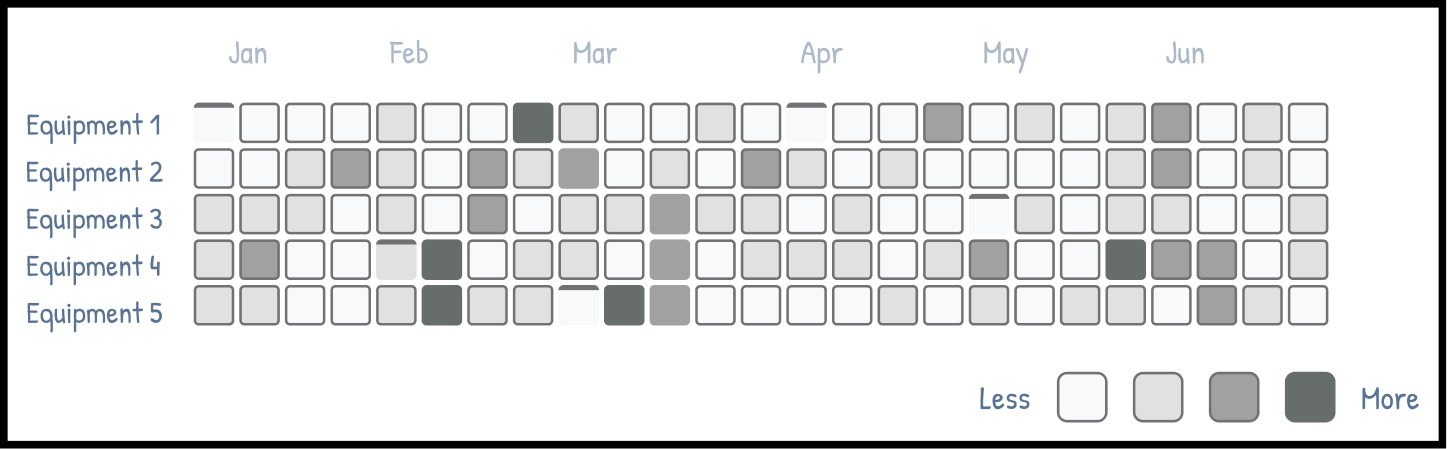

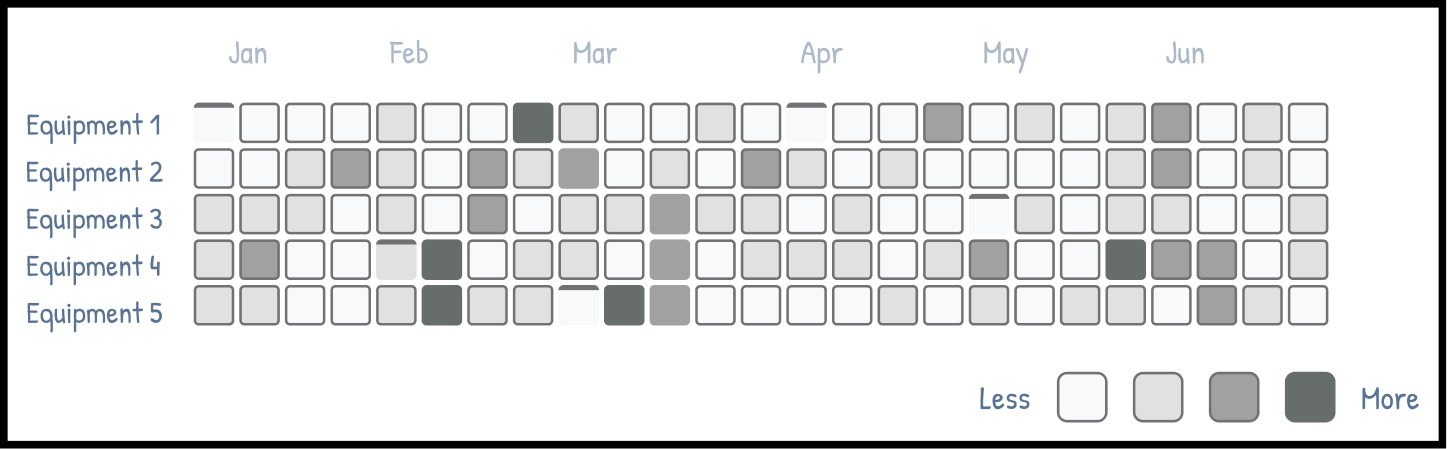

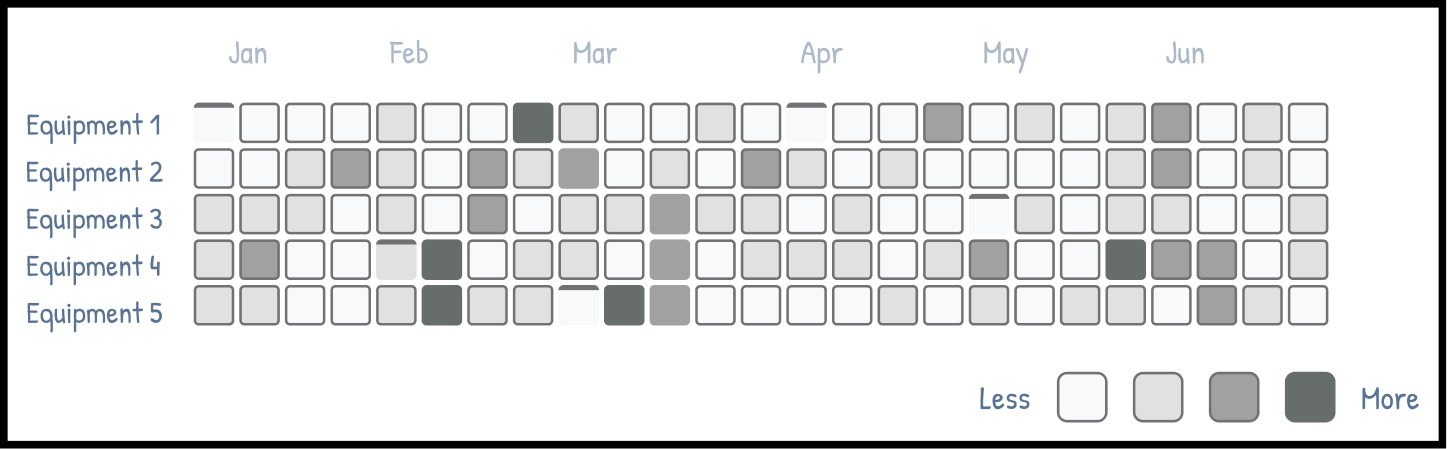

Anomaly Heat map

Highlights when & where anomalies occurred across equipment & time.

Pros & Cons

🟢

Great for spotting temporal patterns

🟠

Doesn’t convey severity or resolution status

Exploration 2

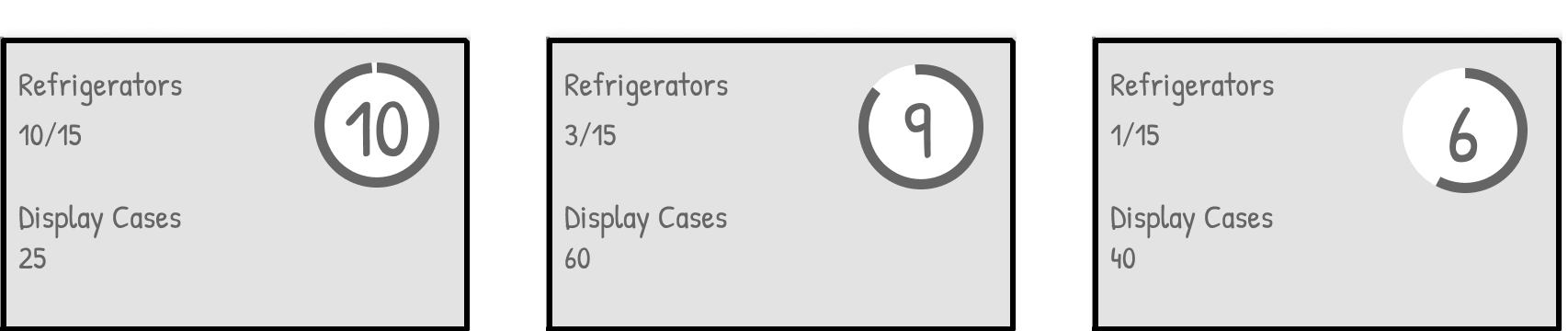

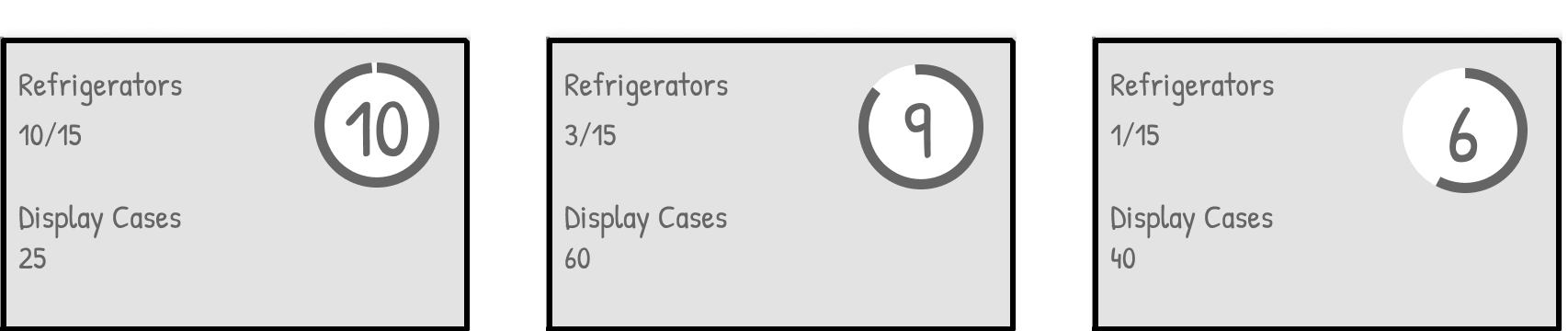

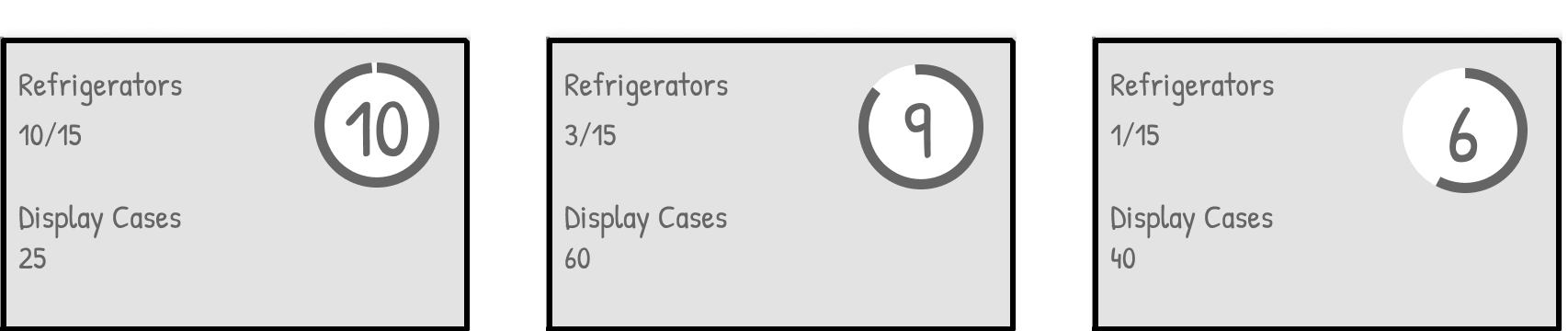

Risk Score Cards

Ranks equipment by failure risk using anomaly trends and past history.

Pros & Cons

🟢

Simple to scan and compare

🟢

Supports prioritization at a glance

🟠

Lacks deeper status context

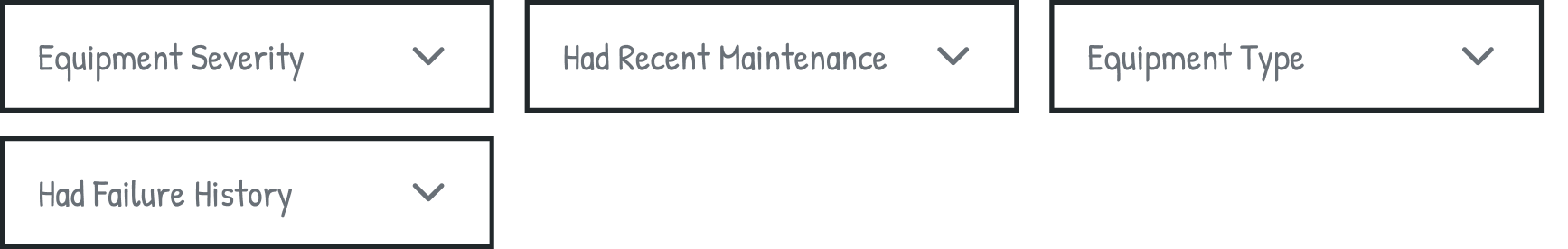

Exploration 3

Filters for Root Cause Analysis

Allow filtering based on severity, recent maintenance, or failure history.

Pros & Cons

🟢

Empowers engineers to narrow down issues quickly

🟢

Helps train AI by surfacing key variables

🟠

Requires upfront data model clarity

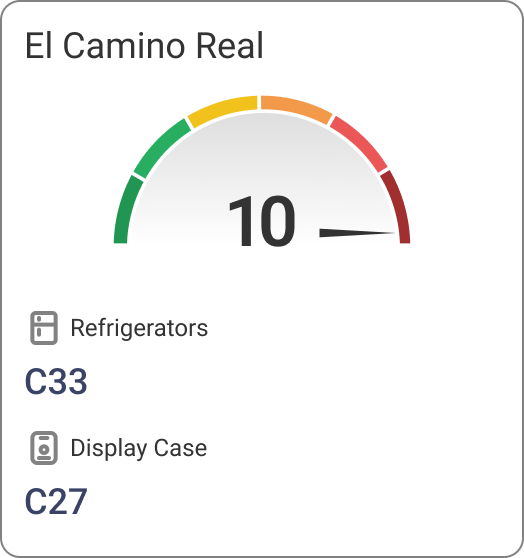

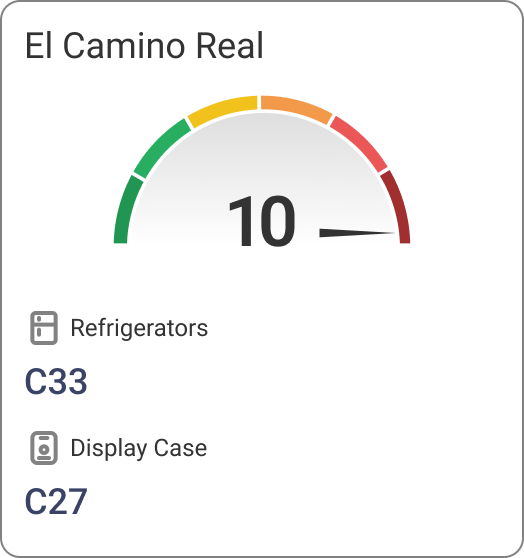

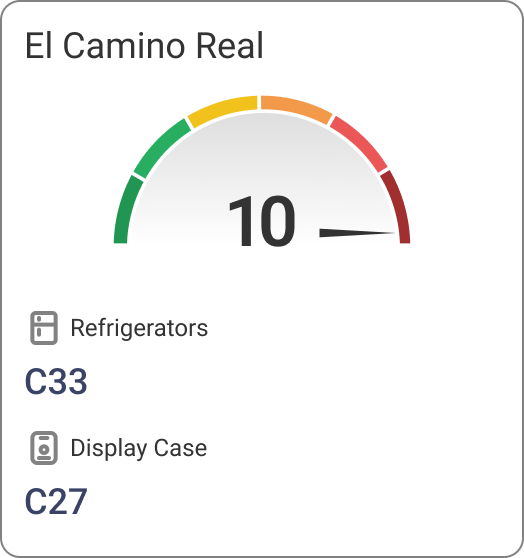

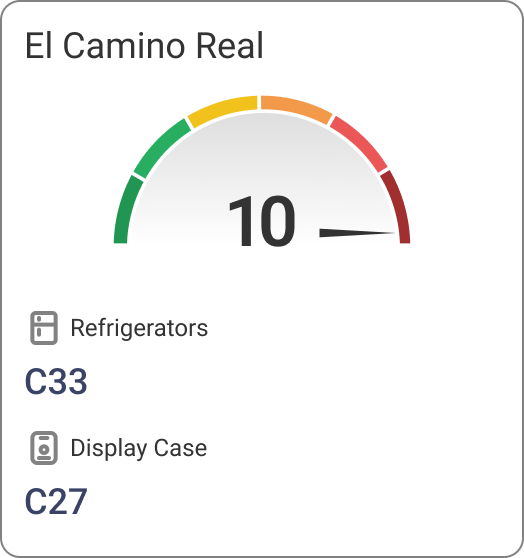

FINALIZED DESIGN OPTION - MVP

Surface highest-risk equipment fast

This landing page helps engineers quickly identify high-risk stores using a color-coded risk score (0–10), based on equipment count and anomaly volume. Key metrics like energy use and sensor anomalies support faster triage and resolution.

FINALIZED DESIGN OPTION - MVP

EQUIPMENT DETAILS VIEW

View top-risk equipment and explore root causes by adding settings or measurements.

USER RESEARCH & VALIDATION

Who we talked to and why it mattered

I engaged with 6 Maintanance Engineers real-world VI Admins to ensure the insights reflected real troubleshooting behaviors.

CANNOT ANALYZE ANOMALIES

Users didn’t understand how risk scores worked and wanted control to explore trends and plot anomalies.

WANTS DIAGNOSTIC HISTORY

Engineers needed access to past issues to compare current anomalies and learn from previous resolutions.

USERS EXPECTED ZOOMABLE GRAPHS

Users wanted interactive graphs that allowed zooming in and out to inspect anomalies more closely.

VERSION 2

Vision: Easy Analysis

Based on the research, we set our vision to improve the analysis experience for our users so that they could diagnose and complete more cases.

To Summarize

EMPATHY MAPPING

User Needs

Identified key investigation gaps for maintenance engineers through interviews and usability testing.

PRIMARY USER

Maintenance Engineers

Focused on resolving equipment anomalies across refrigeration and display case systems.

DESIGN GOAL

Improve Investigation Speed

Built tools to help engineers detect, review, and resolve anomalies faster and with less manual effort.

MEASURE SUCCESS

Product Value

Boosted resolution rates from 10 to 30 anomaly cases/day, delivering a 3× improvement post-launch.

Predictive Maintenance

Proactively reduce downtime and improve field service efficiency

ANTICIPATE FAILURES, NOT JUST RESPOND TO THEM

Before this solution, maintenance engineers relied on customer complaints and repeated site visits to diagnose issues with refrigeration units. This reactive approach led to costly equipment replacements and poor customer experience.I designed the initial experience to help maintenance engineers teach the AI what anomalies may look like. By enabling engineers to analyze equipment behavior and label anomalies, we accelerated the model’s learning while surfacing early warning signs of failure.

Complex Domain

Cross-functional Collaboration

MVP Design Under Ambiguity

MY ROLE

Principal UX Designer

COMPANY

Panasonic

IMPROVING ANOMALY DETECTION AND TEACHING AI

Initial predictive maintenance dashboard enabling engineers to label anomalies and train the model

BACKGROUND

Panasonic

Sells & Maintains Refrigerators

To

Large Scale

Grocery Stores

Nationwide UseAll Over Japan

PROJECT BACKGROUND

Top Frustrations Shared by VI Admins During Contexual Enquriry

The Data Science & Panasonic Cold Chain teams had spent 18 months building an AI model.

It was time to visualize this work. I had only 2 weeks of design time.

The biggest challenge? I didn’t know anything about the users and how do they mitigate issues.

I influenced the team to consider the MVP as an hypothesis to be validated post implementation

DESIGN WORKSHOP SESSIONS

Pre-Design Workshop for MVP Direction

Why it mattered:

Before designing the MVP, we needed clarity on:

- Project goals

- Target users

- The meaning of product scalability

Without this, the MVP risked misalignment with long-term vision.

What I did:

- Facilitated a pre-design workshop to gather diverse inputs

- Defined the agenda and prepared materials in advance

- Ensured participation from product, engineering, and business stakeholders

- Ran warm-up exercises to encourage open discussion

- Captured insights on user needs and scalability definitions

The result:

The session helped frame the MVP with shared understanding. It reinforced that design isn’t done in a silo and ideas emerged from across teams.

DESIGN WORKSHOP OUTPUT

Collaboration With Product Management, Engineering & Data Scientists

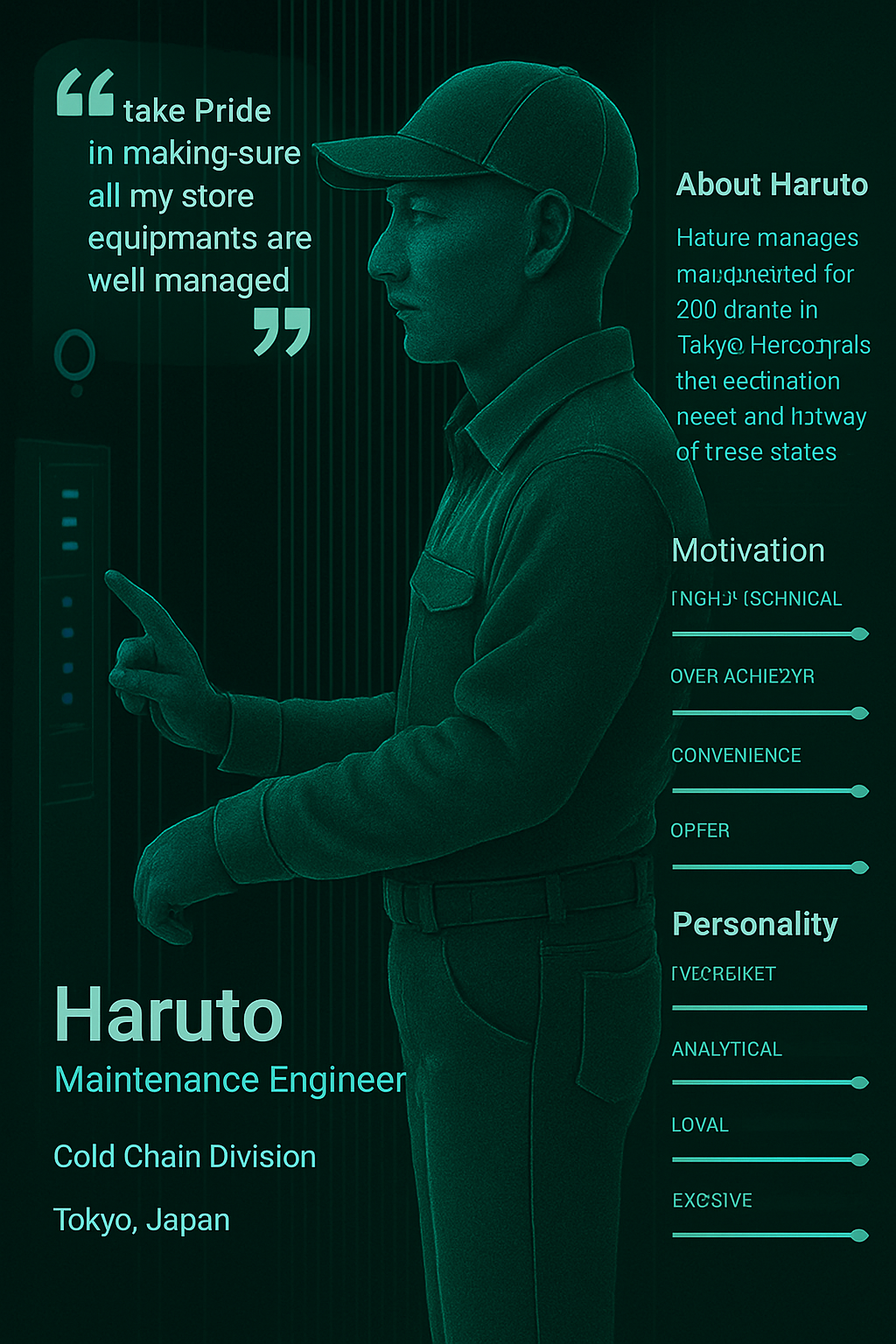

Persona

Created a fictional persona to help the team empathize with end users during early design conversations

Clearly communicated that the persona was a placeholder, and would be refined after conducting user research

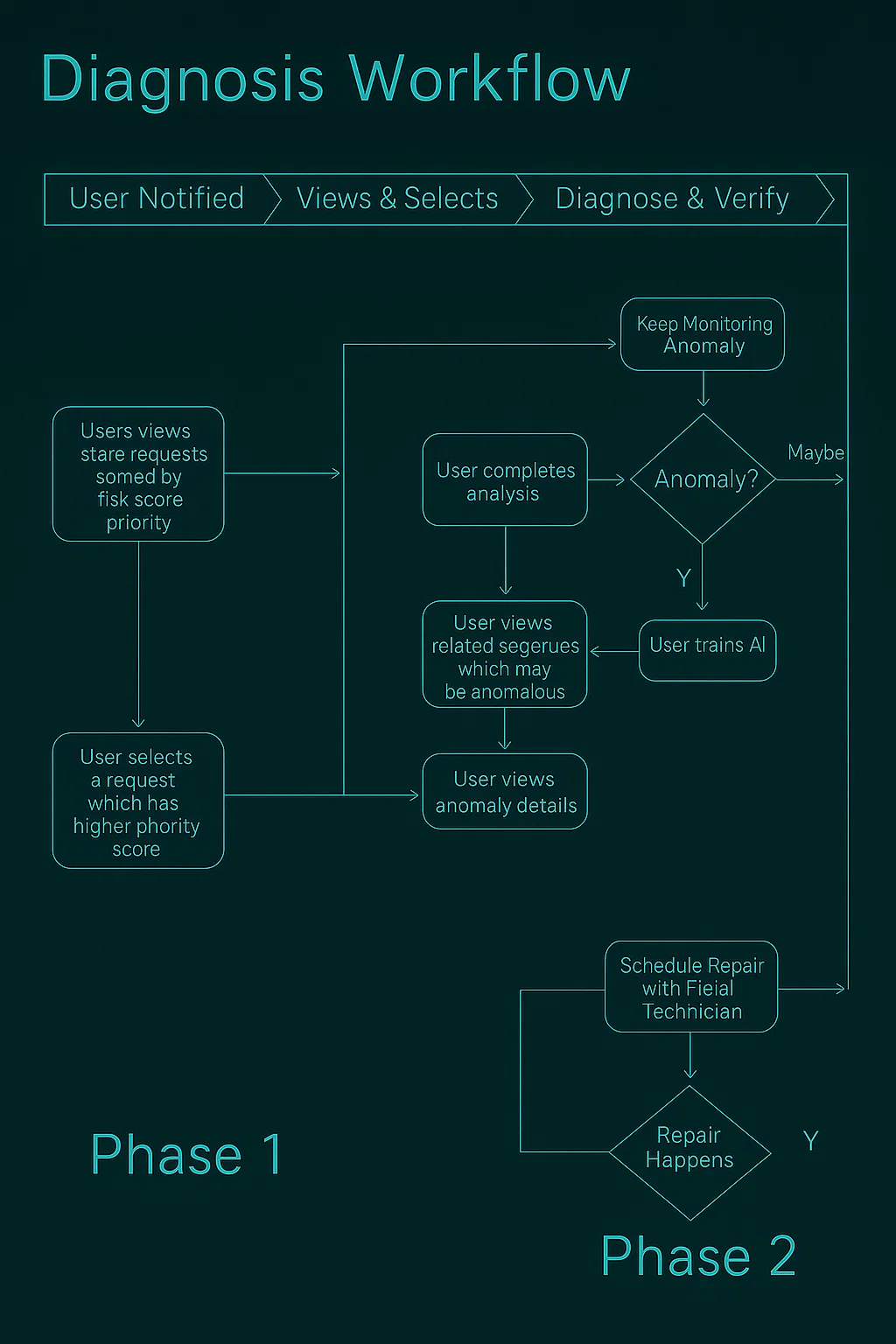

Task Flow

Created a draft task flow to help the team visualize the user journey for anomaly detection

Aligned on early user steps and system touchpoints to inform MVP direction

SETTING THE CONTEXT

Brought Clarity To An Ambiguous Problem Space

Framed the goal as helping maintenance engineers diagnose anomalies, not just detect alerts and product set the success metrics.

User Goal

Help Maintenance Engineers Diagnose Anomalous Equipment Cases Successfully

Success Criteria

Maintenance Engineers should be able to solve 10 Anomaly cases per day

DESIGN EXPLORATIONS

Exploration 1

Anomaly Heat map

Highlights when & where anomalies occurred across equipment & time.

Pros & Cons

🟢

Great for spotting temporal patterns

🟠

Doesn’t convey severity or resolution status

Exploration 2

Risk Score Cards

Ranks equipment by failure risk using anomaly trends and past history.

Pros & Cons

🟢

Simple to scan and compare

🟢

Supports prioritization at a glance

🟠

Lacks deeper status context

Exploration 3

Filters for Root Cause Analysis

Allow filtering based on severity, recent maintenance, or failure history.

Pros & Cons

🟢

Empowers engineers to narrow down issues quickly

🟢

Helps train AI by surfacing key variables

🟠

Requires upfront data model clarity

Equipment Severity

Recent Maintenance

Equipment Type

Equipment Failure

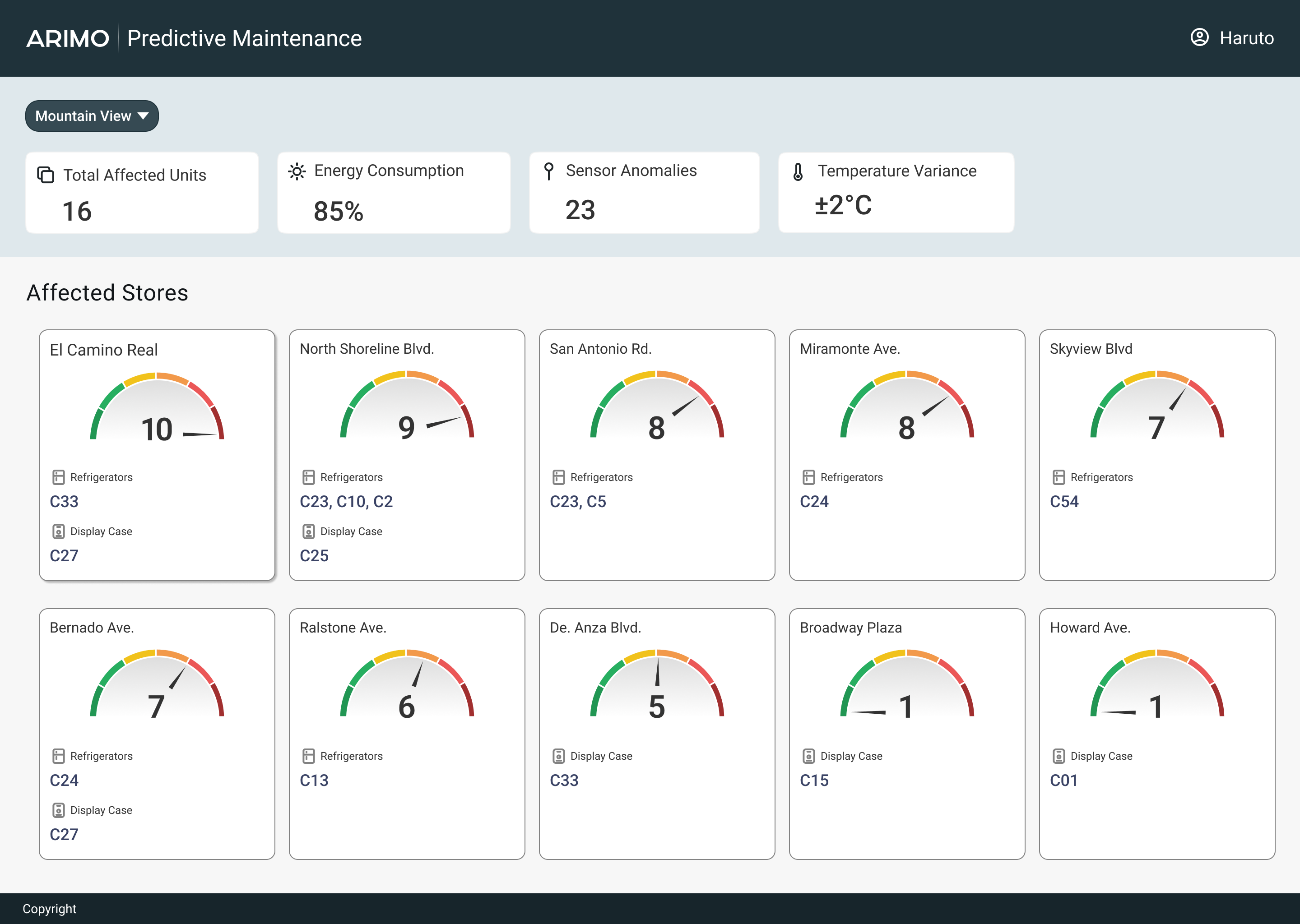

FINALIZED DESIGN OPTION - MVP

Surface highest-risk equipment fast

This landing page helps engineers quickly identify high-risk stores using a color-coded risk score (0–10), based on equipment count and anomaly volume. Key metrics like energy use and sensor anomalies support faster triage and resolution.

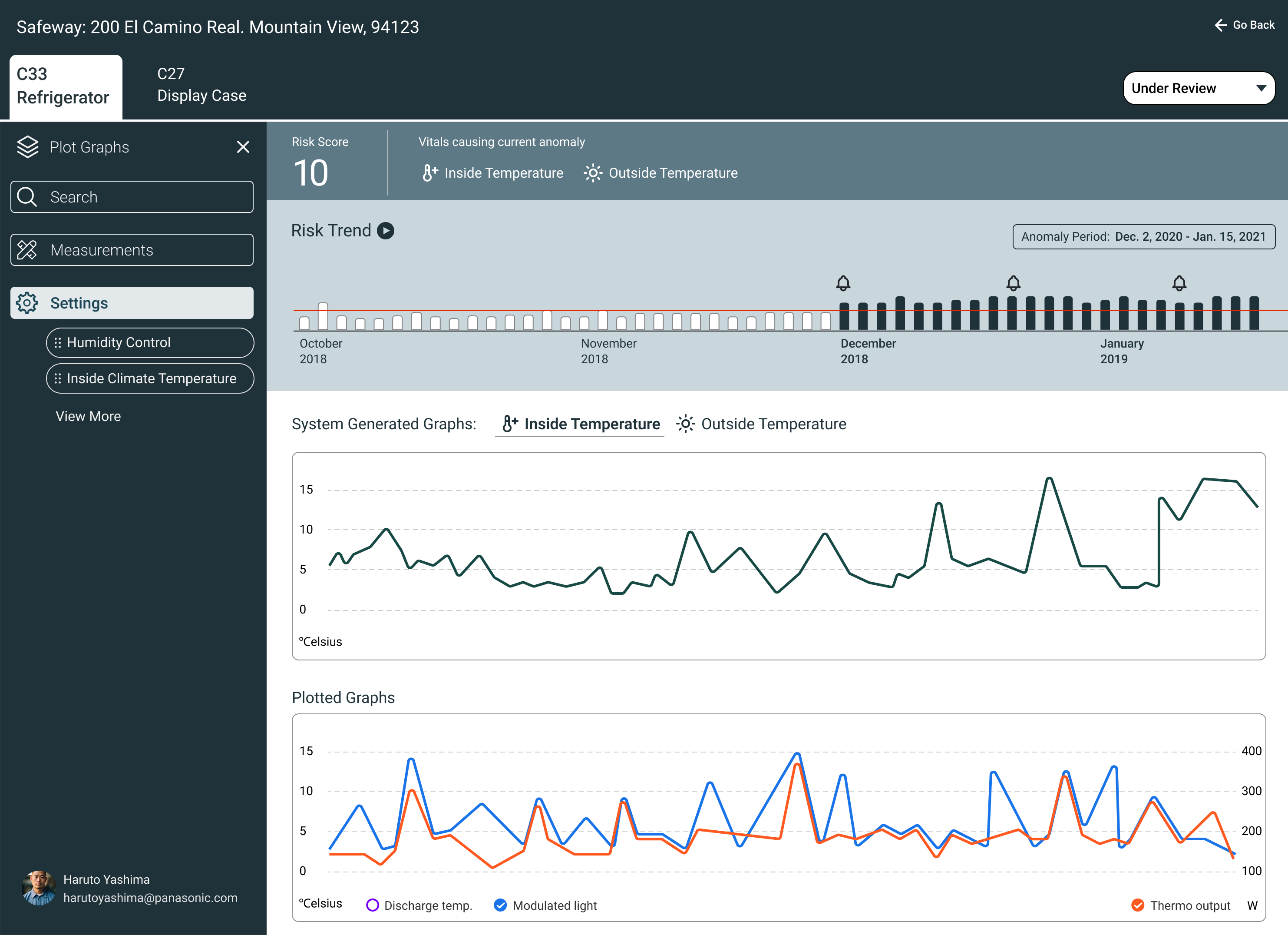

FINALIZED DESIGN OPTION - MVP

EQUIPMENT DETAILS VIEW

View top-risk equipment and explore root causes by adding settings or measurements.

USER RESEARCH & VALIDATION

Who we talked to and why it mattered

I engaged with 6 Maintanance Engineers real-world VI Admins to ensure the insights reflected real troubleshooting behaviors.

CANNOT ANALYZE ANOMALIES

Users didn’t understand how risk scores worked and wanted control to explore trends and plot anomalies.

WANTS DIAGNOSTIC HISTORY

Engineers needed access to past issues to compare current anomalies and learn from previous resolutions.

USERS EXPECTED ZOOMABLE GRAPHS

Users wanted interactive graphs that allowed zooming in and out to inspect anomalies more closely.

VERSION 2

Vision: Easy Analysis

Based on the research, we set our vision to improve the analysis experience for our users so that they could diagnose and complete more cases.

To Summarize

EMPATHY MAPPING

User Needs

Identified key investigation gaps for maintenance engineers through interviews and usability testing.

PRIMARY USER

Maintenance Engineers

Focused on resolving equipment anomalies across refrigeration and display case systems.

DESIGN GOAL

Improve Investigation Speed

Built tools to help engineers detect, review, and resolve anomalies faster and with less manual effort.

MEASURE SUCCESS

Product Value

Boosted resolution rates from 10 to 30 anomaly cases/day, delivering a 3× improvement post-launch.

Predictive Maintenance

Empower developers with end-to-end visibility from build to production.

ANTICIPATE FAILURES, NOT JUST RESPOND TO THEM

Before this solution, maintenance engineers relied on customer complaints and repeated site visits to diagnose issues with refrigeration units. This reactive approach led to costly equipment replacements and poor customer experience.I designed the initial experience to help maintenance engineers teach the AI what anomalies may look like. By enabling engineers to analyze equipment behavior and label anomalies, we accelerated the model’s learning while surfacing early warning signs of failure.

Complex Domain

Cross-functional Collaboration

MVP Design Under Ambiguity

MY ROLE

Principal UX Designer

COMPANY

Panasonic

IMPROVING ANOMALY DETECTION AND TEACHING AI

Initial predictive maintenance dashboard enabling engineers to label anomalies and train the model

BACKGROUND

Panasonic

Sells & Maintains Refrigerators

To

Large Scale

Grocery Stores

Nationwide UseAll Over Japan

PROJECT BACKGROUND

Top Frustrations Shared by VI Admins During Contexual Enquriry

The Data Science & Panasonic Cold Chain teams had spent 18 months building an AI model.

It was time to visualize this work. I had only 2 weeks of design time.

The biggest challenge? I didn’t know anything about the users and how do they mitigate issues.

I influenced the team to consider the MVP as an hypothesis to be validated post implementation

DESIGN WORKSHOP SESSIONS

Pre-Design Workshop for MVP Direction

Why it mattered:

Before designing the MVP, we needed clarity on:

- Project goals

- Target users

- The meaning of product scalability

Without this, the MVP risked misalignment with long-term vision.

What I did:

- Facilitated a pre-design workshop to gather diverse inputs

- Defined the agenda and prepared materials in advance

- Ensured participation from product, engineering, and business stakeholders

- Ran warm-up exercises to encourage open discussion

- Captured insights on user needs and scalability definitions

The result:

The session helped frame the MVP with shared understanding. It reinforced that design isn’t done in a silo and ideas emerged from across teams.

DESIGN WORKSHOP OUTPUT

Collaboration With Product Management, Engineering & Data Scientists

Persona

Created a fictional persona to help the team empathize with end users during early design conversations

Clearly communicated that the persona was a placeholder, and would be refined after conducting user research

Task Flow

Created a draft task flow to help the team visualize the user journey for anomaly detection

Aligned on early user steps and system touchpoints to inform MVP direction

SETTING THE CONTEXT

Brought Clarity To An Ambiguous Problem Space

Framed the goal as helping maintenance engineers diagnose anomalies, not just detect alerts and product set the success metrics.

User Goal

Help Maintenance Engineers Diagnose Anomalous Equipment Cases Successfully

Success Criteria

Maintenance Engineers should be able to solve 10 Anomaly cases per day

DESIGN EXPLORATIONS

Exploration 1

Anomaly Heat map

Highlights when & where anomalies occurred across equipment & time.

Pros & Cons

🟢

Great for spotting temporal patterns

🟠

Doesn’t convey severity or resolution status

Exploration 2

Risk Score Cards

Ranks equipment by failure risk using anomaly trends and past history.

Pros & Cons

🟢

Simple to scan and compare

🟢

Supports prioritization at a glance

🟠

Lacks deeper status context

Exploration 3

Filters for Root Cause Analysis

Allow filtering based on severity, recent maintenance, or failure history.

Pros & Cons

🟢

Empowers engineers to narrow down issues quickly

🟢

Helps train AI by surfacing key variables

🟠

Requires upfront data model clarity

Equipment Severity

Recent Maintenance

Equipment Type

Equipment Failure

FINALIZED DESIGN OPTION - MVP

Surface highest-risk equipment fast

This landing page helps engineers quickly identify high-risk stores using a color-coded risk score (0–10), based on equipment count and anomaly volume. Key metrics like energy use and sensor anomalies support faster triage and resolution.

FINALIZED DESIGN OPTION - MVP

EQUIPMENT DETAILS VIEW

View top-risk equipment and explore root causes by adding settings or measurements.

USER RESEARCH & VALIDATION

Who we talked to and why it mattered

I engaged with 6 Maintanance Engineers real-world VI Admins to ensure the insights reflected real troubleshooting behaviors.

CANNOT ANALYZE ANOMALIES

Users didn’t understand how risk scores worked and wanted control to explore trends and plot anomalies.

USERS EXPECTED ZOOMABLE GRAPHS

Users wanted interactive graphs that allowed zooming in and out to inspect anomalies more closely.

WANTS DIAGNOSTIC HISTORY

Engineers needed access to past issues to compare current anomalies and learn from previous resolutions.

VERSION 2

Vision: Easy Analysis

Based on the research, we set our vision to improve the analysis experience for our users so that they could diagnose and complete more cases.

To Summarize

EMPATHY MAPPING

User Needs

Identified key investigation gaps for maintenance engineers through interviews and usability testing.

PRIMARY USER

Maintenance Engineers

Focused on resolving equipment anomalies across refrigeration and display case systems.

DESIGN GOAL

Improve Investigation Speed

Built tools to help engineers detect, review, and resolve anomalies faster and with less manual effort.

MEASURE SUCCESS

Product Value

Boosted resolution rates from 10 to 30 anomaly cases/day, delivering a 3× improvement post-launch.

Predictive Maintenance

Proactively reduce downtime and improve field service efficiency

ANTICIPATE FAILURES, NOT JUST RESPOND TO THEM

Before this solution, maintenance engineers relied on customer complaints and repeated site visits to diagnose issues with refrigeration units. This reactive approach led to costly equipment replacements and poor customer experience.I designed the initial experience to help maintenance engineers teach the AI what anomalies may look like. By enabling engineers to analyze equipment behavior and label anomalies, we accelerated the model’s learning while surfacing early warning signs of failure.

Complex AI Workflow

Cross-functional Collaboration

MVP Design Under Ambiguity

MY ROLE

Principal UX Designer

COMPANY

Panasonic

IMPROVING ANOMALY DETECTION AND TEACHING AI

Initial predictive maintenance dashboard enabling engineers to label anomalies and train the model

BACKGROUND

Panasonic

Sells & Maintains Refrigerators

To

Large Scale

Grocery Stores

Nationwide UseAll Over Japan

PROJECT BACKGROUND

What Led to the Predictive Maintenance MVP

The Data Science & Panasonic Cold Chain teams had spent 18 months building an AI model.

It was time to visualize this work. I had only 2 weeks of design time.

The biggest challenge? I didn’t know anything about the users and how do they mitigate issues.

I influenced the team to consider the MVP as an hypothesis to be validated post implementation

DESIGN WORKSHOP SESSIONS

Pre-Design Workshop for MVP Direction

Why it mattered:

Before designing the MVP, we needed clarity on:

- Project goals

- Target users

- The meaning of product scalability

Without this, the MVP risked misalignment with long-term vision.

What I did:

- Facilitated a pre-design workshop to gather diverse inputs

- Defined the agenda and prepared materials in advance

- Ensured participation from product, engineering, and business stakeholders

- Ran warm-up exercises to encourage open discussion

- Captured insights on user needs and scalability definitions

The result:

The session helped frame the MVP with shared understanding. It reinforced that design isn’t done in a silo and ideas emerged from across teams.

DESIGN WORKSHOP OUTPUT

Collaboration With Product Management, Engineering & Data Scientists

Persona

Created a fictional persona to help the team empathize with end users during early design conversations

Clearly communicated that the persona was a placeholder, and would be refined after conducting user research

Task Flow

Created a draft task flow to help the team visualize the user journey for anomaly detection

Aligned on early user steps and system touchpoints to inform MVP direction

SETTING THE CONTEXT

Brought Clarity To An Ambiguous Problem Space

Framed the goal as helping maintenance engineers diagnose anomalies, not just detect alerts and product set the success metrics.

User Goal

Help Maintenance Engineers Diagnose Anomalous Equipment Cases Successfully

Success Criteria

Maintenance Engineers should be able to solve 10 Anomaly cases per day

DESIGN EXPLORATIONS

Exploration 1

Anomaly Heat map

Highlights when & where anomalies occurred across equipment & time.

Pros & Cons

🟢

Great for spotting temporal patterns

🟠

Doesn’t convey severity or resolution status

Exploration 2

Risk Score Cards

Ranks equipment by failure risk using anomaly trends and past history.

Pros & Cons

🟢

Simple to scan and compare

🟢

Supports prioritization at a glance

🟠

Lacks deeper status context

Exploration 3

Filters for Root Cause Analysis

Allow filtering based on severity, recent maintenance, or failure history.

Pros & Cons

🟢

Empowers engineers to narrow down issues quickly

🟢

Helps train AI by surfacing key variables

🟠

Requires upfront data model clarity

Equipment Severity

Recent Maintenance

Equipment Type

Equipment Failure

FINALIZED DESIGN OPTION - MVP

Surface highest-risk equipment fast

This landing page helps engineers quickly identify high-risk stores using a color-coded risk score (0–10), based on equipment count and anomaly volume. Key metrics like energy use and sensor anomalies support faster triage and resolution.

FINALIZED DESIGN OPTION - MVP

Spot trends, find root causes

View top-risk equipment and explore root causes by adding settings or measurements.

USER RESEARCH & VALIDATION

Who we talked to and why it mattered

I facilitated research with 6 maintenance engineers to understand their demographics, pain points, and experience with the first version.

CANNOT ANALYZE ANOMALIES

Users didn’t understand how risk scores worked and wanted control to explore trends and plot anomalies.

USERS EXPECTED ZOOMABLE GRAPHS

Users wanted interactive graphs that allowed zooming in and out to inspect anomalies more closely.

WANTS DIAGNOSTIC HISTORY

Engineers needed access to past issues to compare current anomalies and learn from previous resolutions.

VERSION 2

Vision: Easy Analysis

Based on the research, we set our vision to improve the analysis experience for our users so that they could diagnose and complete more cases.

To Summarize

EMPATHY MAPPING

User Needs

Identified key investigation gaps for maintenance engineers through interviews and usability testing.

PRIMARY USER

Maintenance Engineers

Focused on resolving equipment anomalies across refrigeration and display case systems.

DESIGN GOAL

Improve Investigation Speed

Built tools to help engineers detect, review, and resolve anomalies faster and with less manual effort.

MEASURE SUCCESS

Product Value

Boosted resolution rates from 10 to 30 anomaly cases/day, delivering a 3× improvement post-launch.